For almost over a decade, the Compact Linear Collider (CLIC) project has been performing a number of studies to reduce the operational power and energy consumption of the facility. The results are striking. By optimising the accelerator parameters, the design of RF systems, developing high efficiency klystrons and studying the use of permanent magnets, the project has been able to halve its future yearly energy consumption compared to estimates in the Conceptual Design Report, albeit at that time for a 500 GeV initial stage, without reducing the luminosity performance.

The current estimate for the yearly energy consumption of CLIC is around 600 GWh which is less than half the CERN’s current energy use. Equally importantly, several of these studies have grown to become R&D projects on their own providing I important input to the development and upgrade of accelerators, also well beyond accelerators for particle physics.

However, the challenge of establishing a sustainable future accelerator facility demands more than “just” reducing operational power and energy consumption, and adapting to low-carbon power sources. It requires a direct quantification of the ecological footprint from start to end, from the emission of greenhouse gas during operation or production to the consumption of problematic materials.

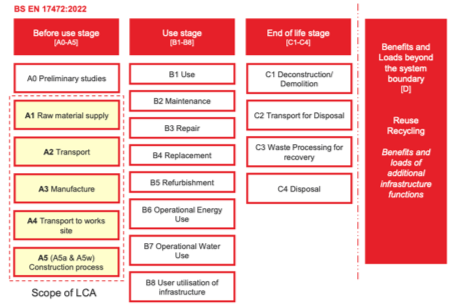

Translating electricity consumption into equivalent CO2 emissions during the operation phase is important. A complete Lifecycle Assessments (LCA) emerges as a much more comprehensive approach, including a much-extended timeline and metric for assessing impacts, as shown in Figure 1.

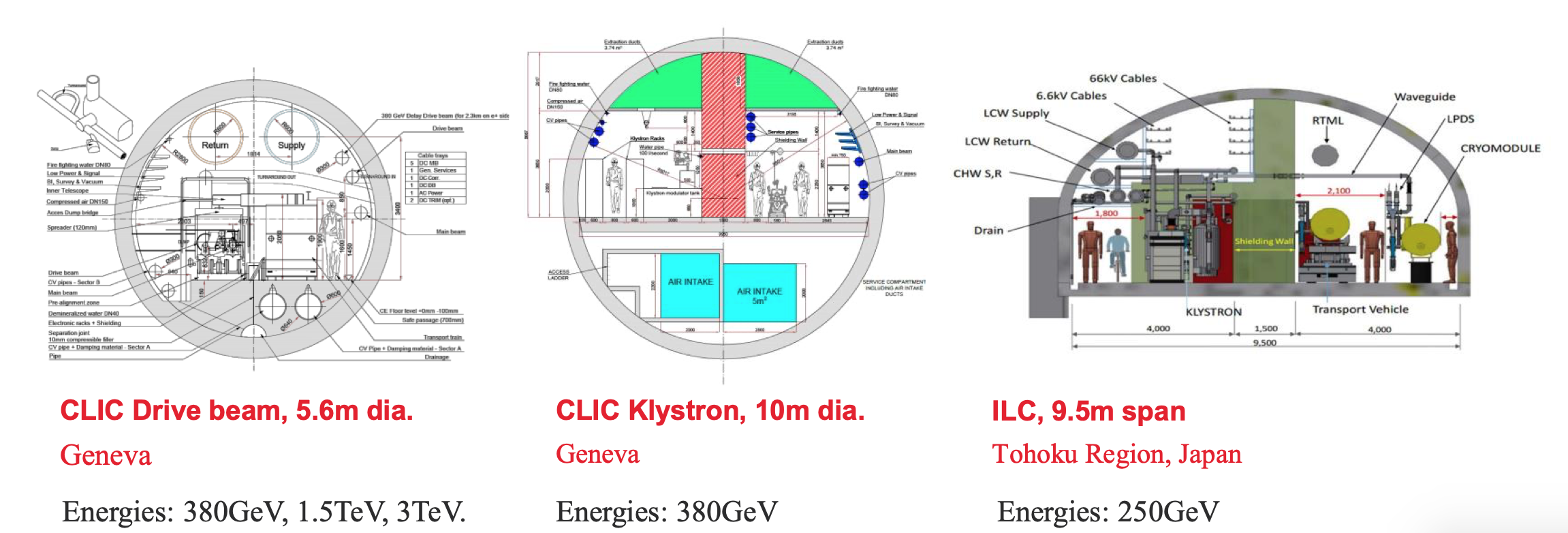

Two large electron-positron linear colliders are currently being studied as potential future Higgs-factories, CLIC at CERN and ILC in Japan. During the last year, a comprehensive LCA has been made by the company ARUP for these two facilities, commissioned by the CERN SCE department for the projects. The study focused on the civil engineering aspects, i.e. of the construction of tunnels, caverns and shafts, and also the surface installations.

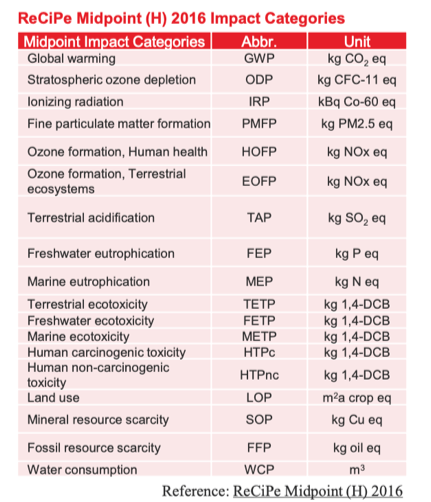

An LCA of this type brings into focus the construction impact, embedded carbon in materials, upgrades and decommissioning, and many more parameters than CO2 emission, as water consumption, radioactive materials and more. The full list is shown in Figure 2 from the report.

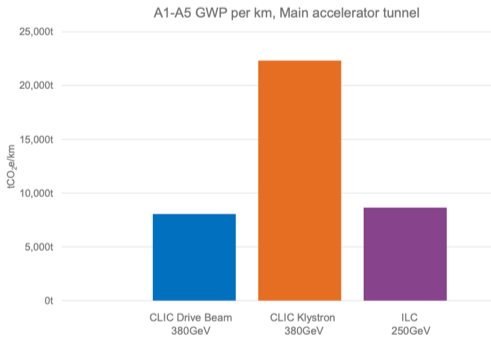

The carbon emissions, holds surprising results and highlights the huge impact of construction. For instance, one kilometre of tunnelling approaches 10 kton/CO2 equivalent emission, as shown in Figure 3.

For comparison, this level of emissions, for one km, is close to what we can hope to reach by 2050 for an annual operational energy consumption of 1 TWh (today, September 2023, the emission would be a factor 4 higher in France). Even if this is an optimistic projection for electricity production carbon intensity in 2050, the construction impact in terms of CO2 emissions are substantially more important than we expected. Additionally, the construction impact will come much earlier, is harder to reduce and does not include yet the accelerator components, upgrades and decommissioning.

It seems clear that an LCA methodology brings a much more complete picture of how a sustainable facility should be optimised. It puts an increased emphasis on the construction and civil engineering materials, while for the accelerator part, it shows the impact of choosing the right materials, the best processing methods to turn them into components, as well as a responsible purchasing with knowledge of the emissions connected to producing all parts.