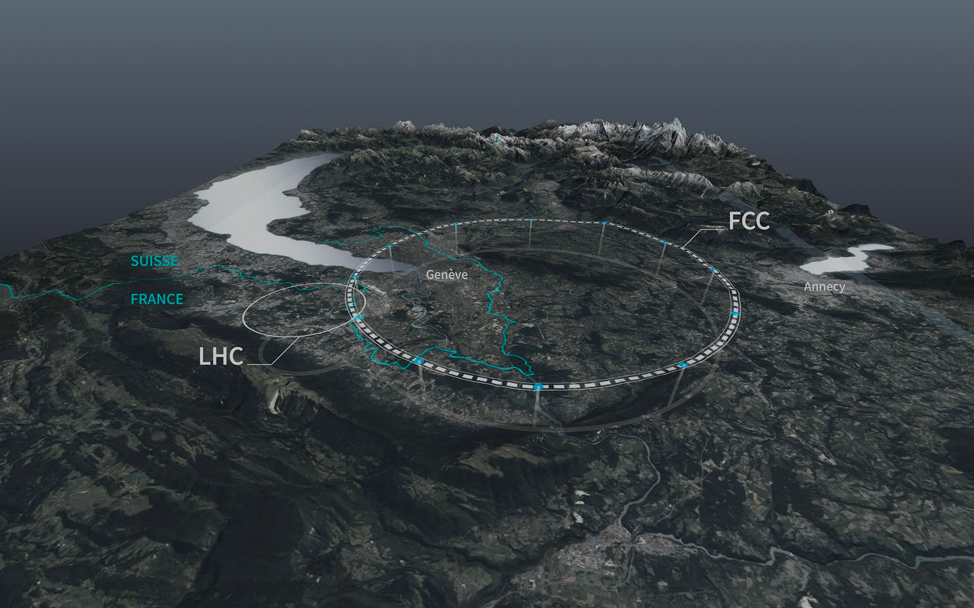

In January 2020, the European Strategy Group concluded that an electron positron Higgs factory is the highest-priority next collider, thus giving to CERN the study the feasibility of a Higgs factory, followed by a future hadron collider. The proposed 100 km-circumference Future Circular Collider (FCC) at CERN, whose financial and technical feasibility is currently under study, offers unprecedented potential in terms of the reach on phenomena beyond the Standard Model (SM).

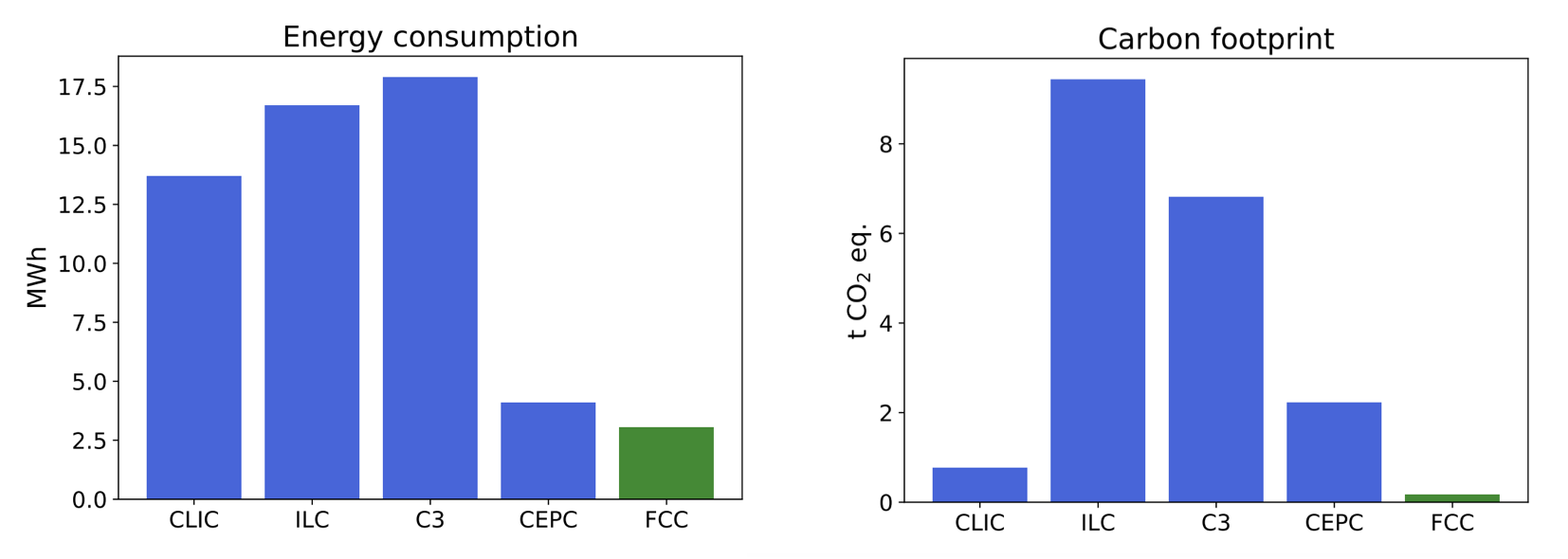

The carbon footprint of a future Higgs factory could vary by almost a factor of 100, depending on the chosen design and its location (arXiv:2208.10466). That is the conclusion of a recent analysis, comparing the environmental impact of different proposed Higgs factories per physics output. The challenge is to design a facility that can deliver the science with minimal impact on the climate and according to their results, an electron-position Higgs and elecroweak factory (FCC-ee) is the best facility currently on the table in this respect, as it would consume less energy and produce lower carbon emissions per Higgs boson produced than competing designs.

For Higgs factories, the ability to do science is directly related to the number of Higgs bosons produced. Take a Higgs factory A that produces 40,000 Higgs bosons / year for an energy of 0.5 TWh, and a Higgs factory B produces 400,000 Higgs bosons per year for an energy of 1 TWh. If we need one million Higgs bosons to do our science, the Higgs factory A will need 25 years to get there, while the Higgs factory B only 2.5 years. In terms of energy, this corresponds to 12.5 TWh spent for the Higgs factory A and only 2.5 TWh for the Higgs factory B (although the B factory consumes twice more energy per year than A). This illustrates how important it is to take into account the physics output that different Higgs factories can deliver to enable a rigorous scientific programme.

One concludes that the energy consumed per year is therefore not a good estimate. Instead, the energy consumed per Higgs boson, 12.5 MWh for A and 2.5 MWh for B is the right estimator to evaluate the total energy that will be spent at the end. In their paper, the authors derive a similar analogy with two factories that produce cars, to make clearer the importance of taking into account the environmental impact per physics output.

In their analysis, the two authors found that the FCC was the most energy-efficient design, consuming 3 MWh of electricity for each Higgs boson it produced. The next best was the CEPC at 4.1 MWh per Higgs boson, while the most energy intensive design is the C3 (18 MWh/Higgs boson). Moreover, the carbon footprint of the FCC could be further improved if the design increased the number of interaction points from two to four. In this scenario each Higgs boson produced would consume 1.8 MWh of energy and emit 0.1 tonnes of CO2 equivalents.

Further elements, including the construction impact as well as the environmental footprint of the detectors will be addressed in a forthcoming paper. In a time that we witness a climate change of unprecedented proportions it is critical to take environmental concerns into account. The choice for the next generation of facilities of a given footprint should strive to maximize the scientific outcome.