Although particle accelerators have great potential for useful applications for society, they are often criticised for being too big, too expensive, and too energy-consuming for the environment.

Funded by the European Union, the I.FAST project brings together a large consortium of European institutes and industries involved in accelerators to explore the technological paths that could change this status quo.

In 2021, it launched a €1M fund aimed at identifying innovative solutions with a positive impact on the environment. Following a fast-track call for applications, eight projects were selected in fields as varied as permanent magnet solenoid to increase the power efficiency, to high-temperature superconductors to optimise energy savings.

Luca Garolfi (CERN & TERA Foundation) tells us about the Innovation Fund he is now coordinating on behalf of I.FAST, taking over from Marcello Losasso (CERN) who initially launched the project.

Accelerating News: A year and a half ago, I.FAST presented the eight beneficiary projects. What was the ambition of the I.FAST Innovation Fund?

Luca Garolfi: The I.FAST Innovation Fund (IIF) aimed at intersecting the nine thematic areas of I.FAST with the European Community priority agenda. That allows for tackling similar priorities while connecting the accelerator community and societal topics. Also, it stimulates the accelerator technology innovation potential by encouraging the I.FAST beneficiaries to identify innovative solutions with viable industrial or commercial potential. More specifically, the underlying idea of IIF is to engage industries with I.FAST partners, to develop innovative ideas potentially able to impact the environment and sustainability of Particle Accelerators. Also, the Fund intended to finance projects at both early development and prototype stages, with technical maturity up to Technology Readiness Level (TRL)1 of 4 (validated in the laboratory) and to bring them to a higher level sufficient to go for industrialisation or commercialisation.

AN: Where do things stand today as you present the results of the projects?

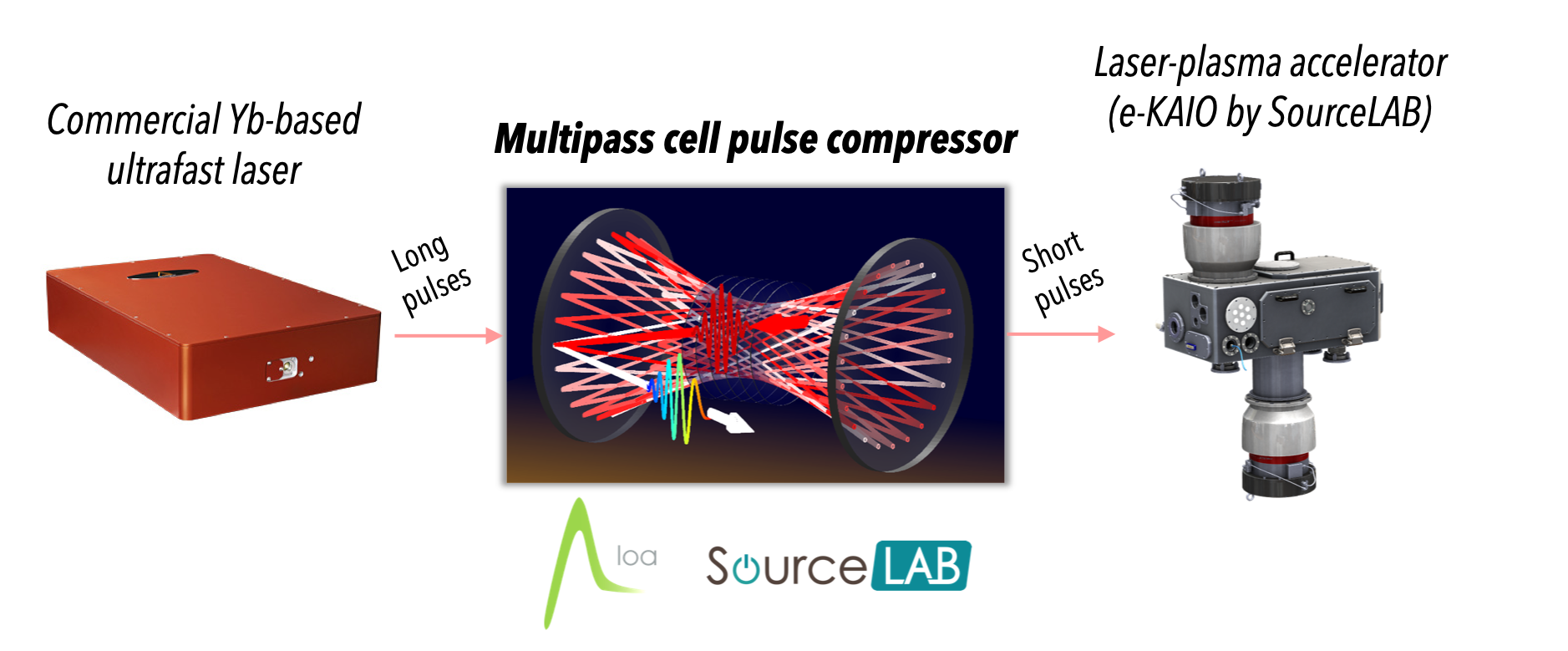

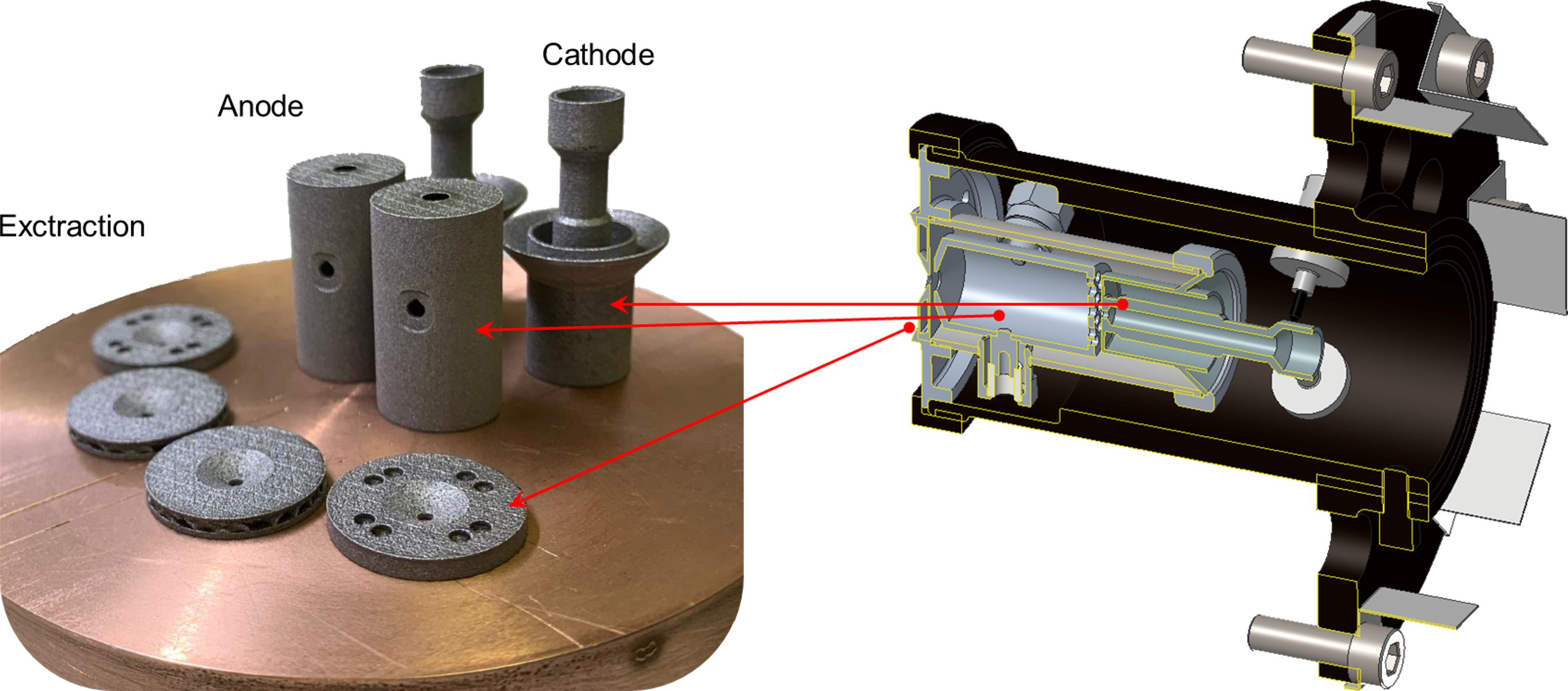

LG: Nowadays, two projects are developing high-efficiency RF sources for reducing the power consumption needed for running current and future accelerator facilities. Two projects are related to novel additive manufacturing techniques, which allow the realisation of large accelerator components with complex shapes by significantly reducing the process complexity and the number of raw materials and quantity. Two projects aim to prove the effectiveness of high-temperature superconducting (HTS) materials for a drastic decrease in cryogenic power requested for operation. Therefore, HTS can significantly reduce the environmental impact and energy costs of SRF accelerator technology. One project is developing a state-of-the-art laser system allowing plasma-based electron acceleration. This technology has large potential for Very High-Energy Electrons for industrial and medical applications. One project is devoted to the fabrication and experimental tests of a field-emission compact accelerator acting as a high-brightness electron source for several academic and industrial applications. This accelerator requires minimal RF equipment, thus avoiding ordinary complex laser and RF power systems.

AN: Can you tell us about the most promising projects?

LG: CNRS/LOA is a pioneer and world leader in ultrafast laser and laser-plasma interaction science and operates state-of-the-art high peak power ultrafast laser and Laser-Plasma Accelerator (LPA) systems. Thanks to the Fund, it is developing a compact LPA accelerator in partnership with a private company that provides access to LP tools for research, energetic radiation, and particle sources. At the moment, TRL is four, but their experimental activities and tests could enhance it to five or six. The company is interested in enhancing its technology and application, especially in the Very High Energy Electron radio-therapy domain.

INFN-Padua, Padua University, and INFN-Legnaro are developing innovative ion sources via Additive Manufacturing (AM) technology, exploring the possibility of improving the reliability of assembly procedures and ionization performance. They have already manufactured some critical components and substituted them with some mechanical components manufactured with the standard procedure within a radio-isotope factory at CERN. Also, they have successfully commissioned the accelerator while proving high reliability. Now, they are transitioning from TRL four to TRL five. This AM is mature and caught the interest of SAES Getters S.p.a, a famous firm in the vacuum market, in pursuing viable strategies toward commercialisation.

Other projects are at a lower TRL but are showing interesting progress. Some of them focus on design optimisation, and numerical simulations. Others are concentrated on the experimental activities and their future results may determine the success and the maturity of their technology.

AN: How do you see the future of these projects?

LG: Some of them made significant progress on designing, manufacturing techniques and processes, prototype assembling, and experimental tests. They increased their TRL and interest in pursuing viable strategies for commercialisation. These projects established an efficient and fruitful synergy with the industrial partners. The Innovation Fund implemented a tight synergy with I.FAST WP3, that is responsible for knowledge transfer and business opportunities. We will support any business case analysis, intellectual property protection, and viable strategies to file patent applications.

[1] The definition of Technology Readiness Levels in European projects can be found at https://ec.europa.eu/research/participants/data/ref/h2020/wp/2014_2015/annexes/h2020-wp1415-annex-g-trl_en.pdf